Focus on AGV industry for 17 years

Focus on AGV industry for 17 years

Focus on AGV industry for 17 years

Focus on AGV industry for 17 years

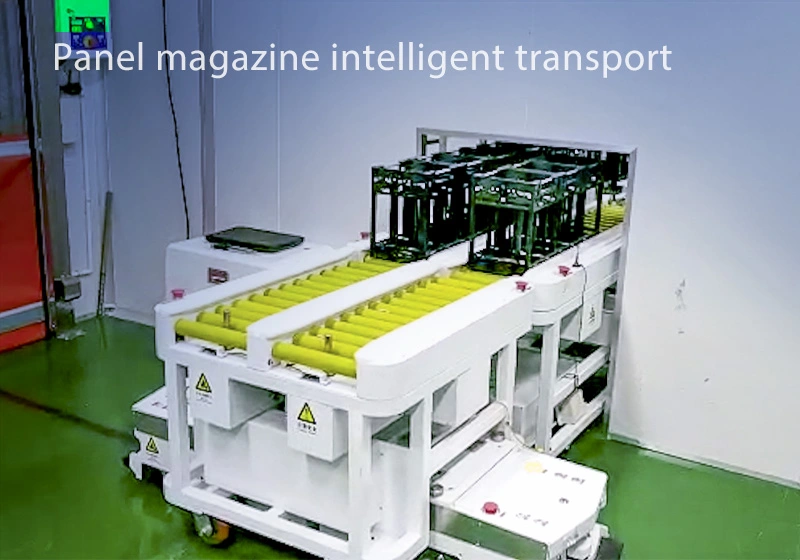

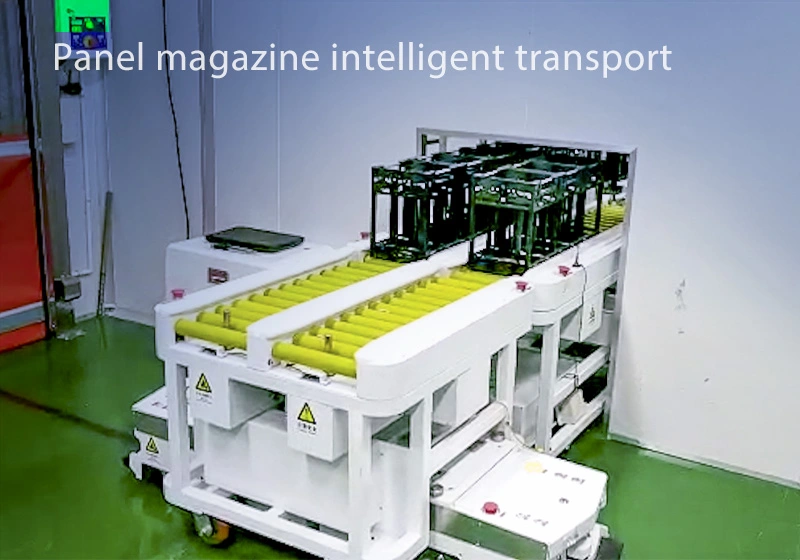

| Navigation | QR code / SLAM | Driving mode | Dual-wheel differential drive |

| Vehicle dimensions | L900*W650*H300(mm) | Charging mode | Bumping charging |

| Moving direction | Move forward/backward, rotate | Battery | Lithium battery |

| Load capacity | 600KG | Communication | WiFi/5G |

| Rated speed | 0~72m/min(QR code navigation) 0-60m/min(SLAM) | Safety warning | Light + Audio |

| Guidance accuracy | ±5mm(QR code) ±10mm(SLAM) | Safety sensing range | ≤3m(adjustable) |

| Stopping accuracy | ±5mm(QR code) ±10mm(SLAM) | Safety protection | Front obstacle detecting sensor+Mechanical anti-collision bumper +Emergency-stop switch |

| Lift height | 50mm |

90-degree corner turning or 180-degree in-situ rotation & turning around, workable in narrow space.

Maps self-learning, automatically update running maps according to on-site environment during working, so as to greatly improve environmental applicability.

Link with lifts with cross-floor function.

The primary positioning accuracy can reach ±10mm, and the secondary positioning accuracy can reach ±5mm.

Euipped full-servo driving, it can speed up quickly (0-72 meters only needs 3 seconds), and also with fast rotation function (in-situ rotation only needs 3 seconds).

Multiple AGVs synchronization linkage, applied to complex material handling scenarios.

Autonomous moving according to scheduling without manual intervention in production process.

With Malfunction self-inspection function, remote malfunction diagnosis and self-recovery functions.

AGVs will move to charge station and do charging job automatically when they are detected to be in low power status,response time can be 24 hours per day so as to increase productivity.

Equipped laser obstacle detection sensor, mechanical anti-collision device and acoustic-optic warning to ensure safe operation.