Focus on AGV industry for 17 years

Focus on AGV industry for 17 years

Focus on AGV industry for 17 years

Focus on AGV industry for 17 years

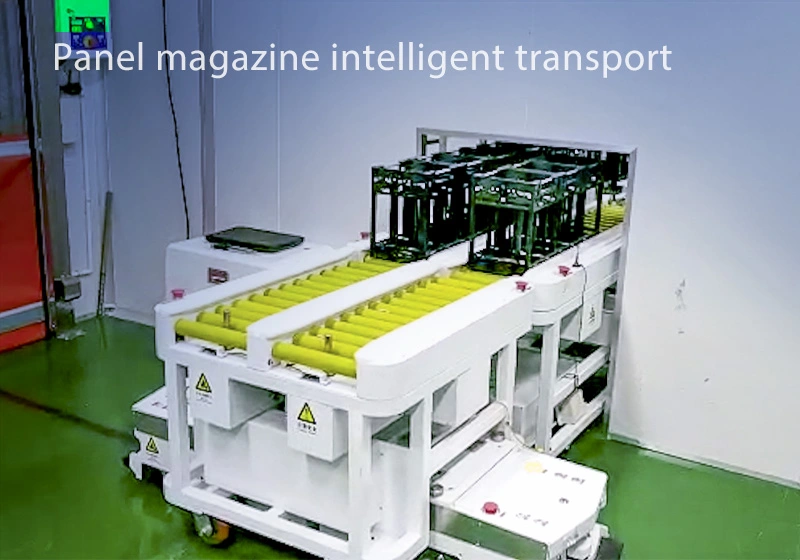

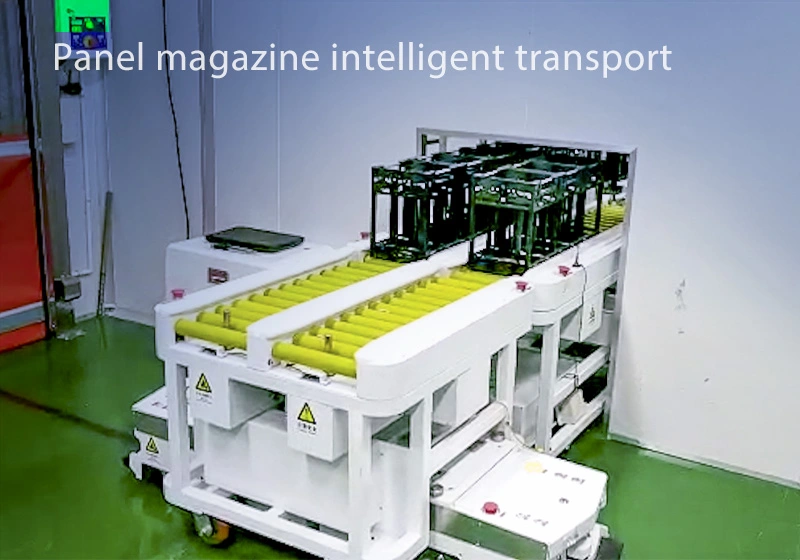

| Navigation | Magnetic / QR code robot navigation | Stopping accuracy | ±10mm |

| Vehicle dimensions | L2000*W950*H400(mm) | Driving mode | Steering-wheel drive |

| Moving direction | Move forward/backward/sideways, rotate | Charging mode | Side/Ground charging |

| Load capacity | 2000KG | Battery | Lithium battery |

| Rated speed | 0~45m/min | Communication | WiFi/5G |

| Lift height | 50mm | Safety warning | Light + Audio |

| Turning radius | 1200mm (magnetic) | Safety sensing range | ≤3m(adjustable) |

| Guidance accuracy | ±10mm | Safety protection | Front obstacle detecting sensor+Mechanical anti-collision bumper +Emergency-stop switch |

CASUN latent lift AGV is adapted to four types of navigation methods, including SLAM navigation, QR code navigation, magnetic tape navigation and laser navigation. Customers could choose the most suitable navigation method according to their on-site needs, thus ensuring the best solution.

Equipped with AGVS and PMS intelligent management system, the latent lift series can not only realize intelligent scheduling and traffic management but also has the ability to pre-programmed the traffic, thus improving AGV run efficiency. QR code-guided latent lift AGV can schedule checkerboard style routes which allow a large number of AGV to operate efficiently in the same area at the same time.

The rated load capacity of the Latent Lift series is between 200KG and 3500KG. If a larger load capacity is needed, we offer customized AGV types according to on-site requirements.

The Latent Lift AGV and Ca Sun's intelligent management system can form the material sorting system which could be applied in the logistics and e-commerce sorting industry.

The navigation precision varies from navigation method, the highest precision is up to ±5mm, even to ±3mm after second positioning.

In practical applications, it can be combined with a robotic arm to form a new composite robotic system that can complete more complex actions such as identification, grasping, and picking.

The Latent Lift AGV and the intelligent system can form a sorting system, equipped with a camera, the sorting system can sort material according to its code. Thus the latent lift AGV is applied in warehousing industries such as e-commerce logistics, clothing and footwear industry. Moreover, it can also transport large materials in the lithium battery industry, automotive industry, 3C electronics and home appliances industry.

Casun C2-32 collaborative mobile robots can generate and process information, so it can perform tasks and realize self-management without human intervention. In this way, this omnidirectional AGV can not only perform repetitive or dangerous processes, but also decide its own path, or adjust its movements at any time based on the data collected in real-time.

Our C2-32 collaborative mobile robots enable machine-to-machine-based (M2M) communication by creating decentralized systems and the possibility for robots to interact with humans through an integrated interface.

Casun C2-32 Omnidirectional AGV collaborative mobile robots with intelligent navigation are highly adaptable because they are able to change how they work according to the changes or needs of the work environment, such as adjusting speed or creating alternative routes.

90-degree corner or 180-degree in-situ rotation and turning or moving sideways for the omnidirectional lifting AGV.

According to different application scenarios, two-dimensional code or magnetic stripe navigation for the collaborative mobile robots can be selected.

The collaborative mobile robots can interact with the elevator to complete the operation of automatically going up and down floors.

The primary positioning accuracy of omnidirectional AGV can reach ±10mm, and the secondary positioning accuracy can reach ±5mm.

Equipped with a full servo drive, the omnidirectional AGV can increase the speed quickly (0-72 meters per minute only takes 3 seconds), and has a fast rotation function (only 3 seconds for in-situ rotation)

Synchronous linkage of multiple collaborative mobile robots is suitable for complex material handling scenarios.

No manual intervention is required in the production process, and the scheduling system is fully automatic.

With fault self-checking function, remote fault diagnosis and self-recovery function for the collaborative mobile robots.

When the AGV detects a low battery state, the omnidirectional lift AGV will automatically move to the charging station for charging. The online time can reach 24 hours a day to improve productivity.

Equipped with laser obstacle detection sensor, mechanical anti-collision device and sound and light warning to ensure safe operation.