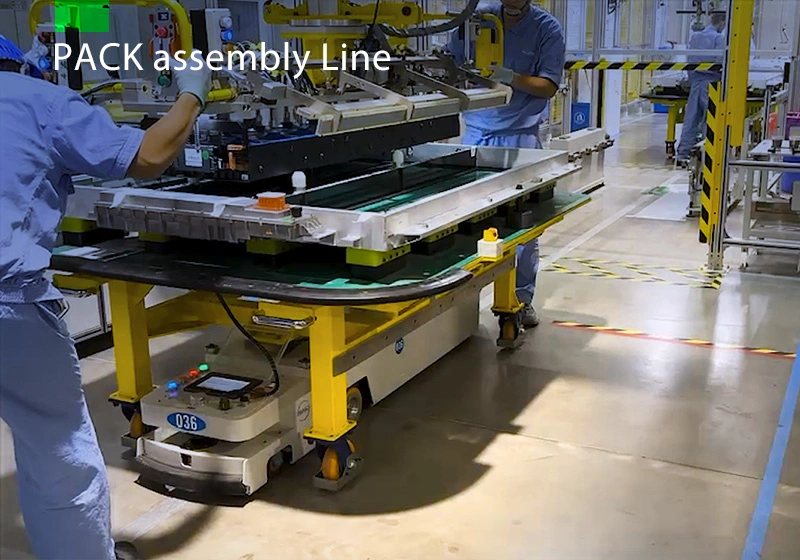

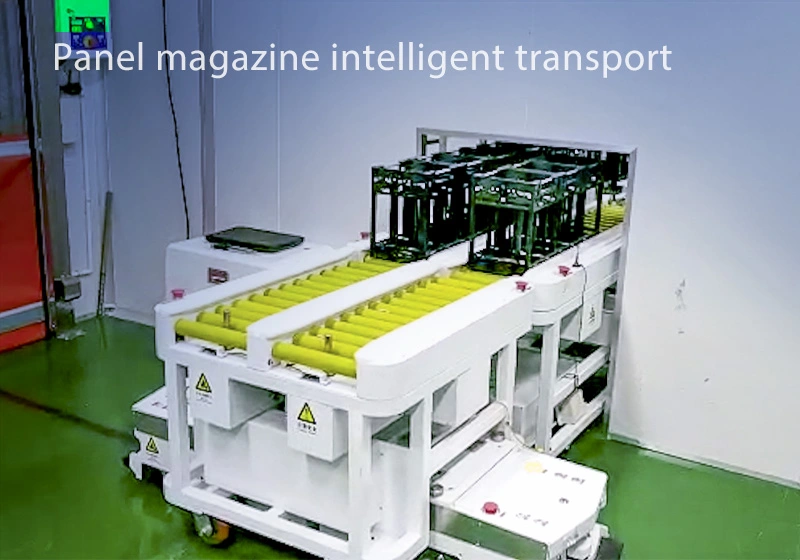

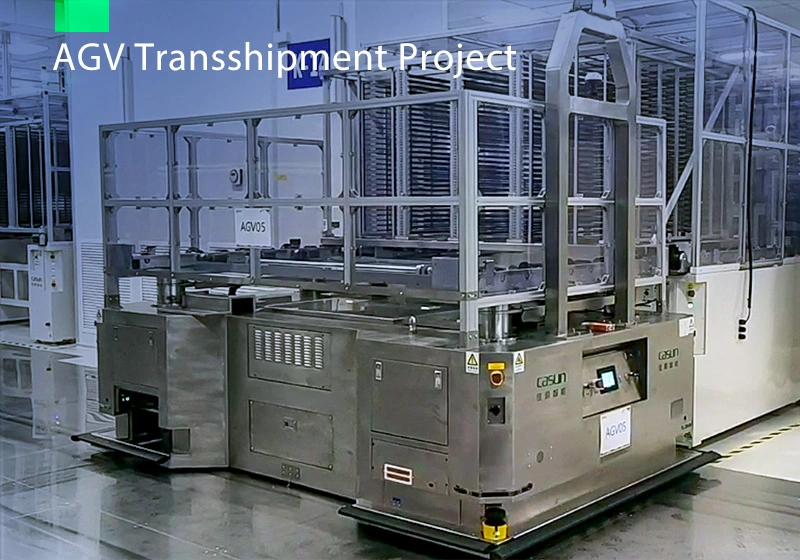

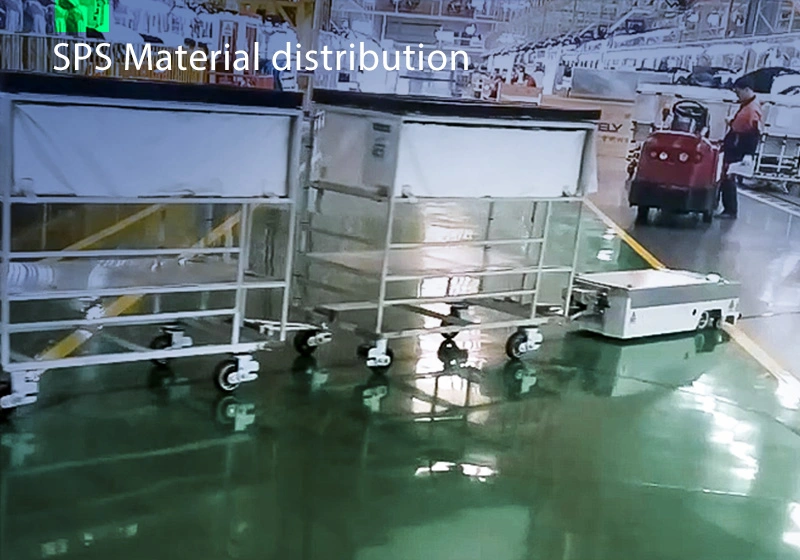

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

| Dimensions | L2000*W1200*H560 (mm) | Acceleration | 0.35m/s² |

| Maximum load | 3500kg | Maximum walking speed | 1.0m/s / 0.8m/s |

Body weigh | 1000kg | Maximum gradeability | ≤3° |

Rotation diameter | 2330mm | Battery Type | Lithium battery |

| Relative rotation | NO | Charging method | Side charging |

Jacking Platform Dimension | 1770*1160mm | Charging time | ≤1H |

| Max jacking stroke | 50mm | Rated battery life | 8H |

Navigatio | Magnetic / QR code robot navigation / SLAM | Communication method | RF / WiFi / 5G |

Navigation accurac | ±10mm / ±10mm / ±15mm | Safety Alert | Light warning , Voice broadcast |

Stop accurac | ±10mm / ±5mm / ±10mm | Safe sensing range | ≤3m(adjustable) |

Stop angle accurac | ±1° | Security |

|

Walking directio | Forward, backward, rotate, sideways | Operating ambient temperature | -10℃ ~ 45℃ |

Drive mode | Steering wheel drive | Operating environment | No dust, flammable, explosive and corrosive gases |

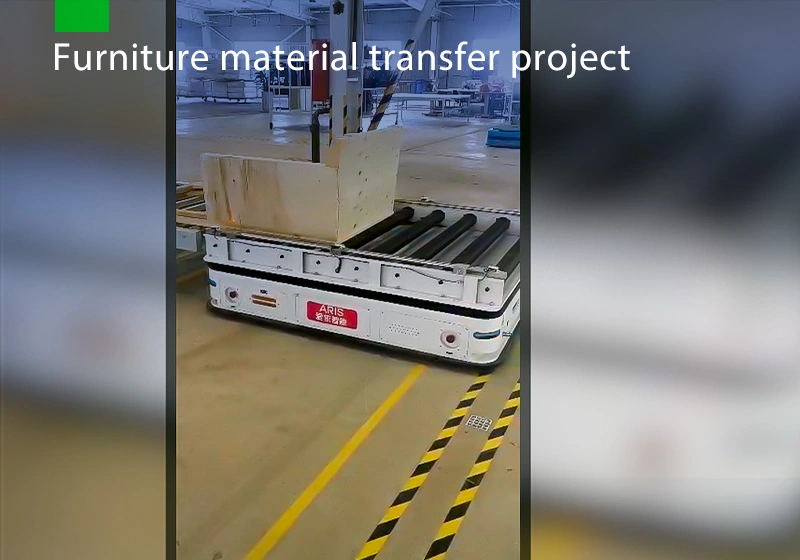

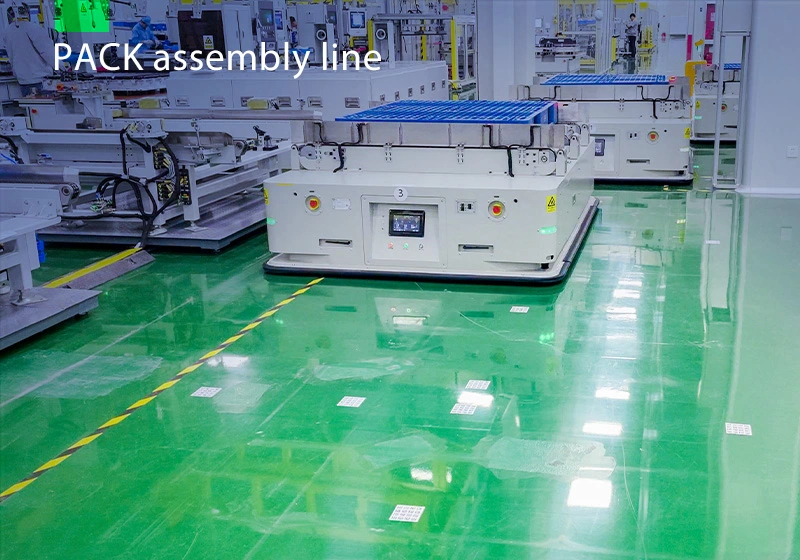

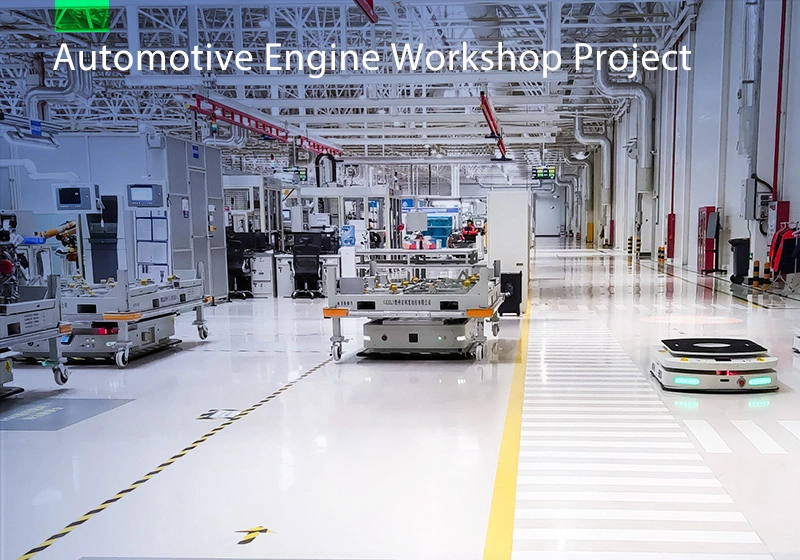

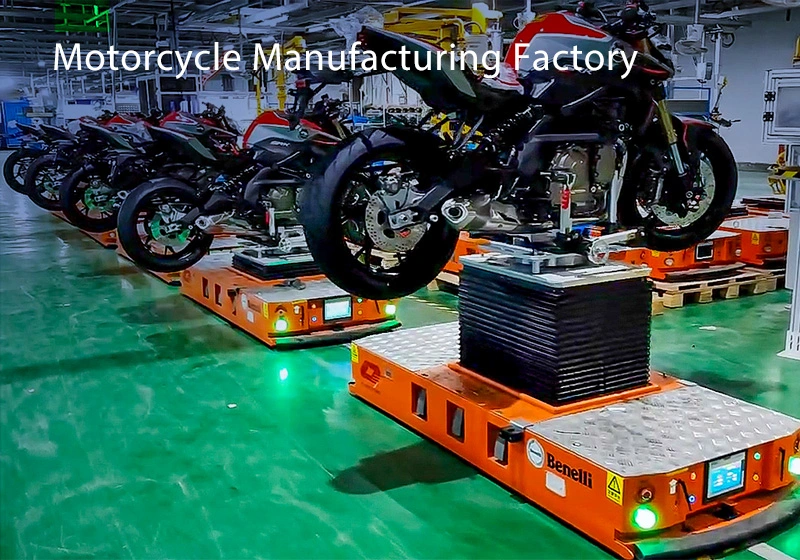

The carrying capacity can reach 3500KG, and the full-load moving speed can reach 45m/min.

The map is self-learning, and the operation map is automatically updated according to the on-site environment when working, which greatly improves the environmental adaptability.

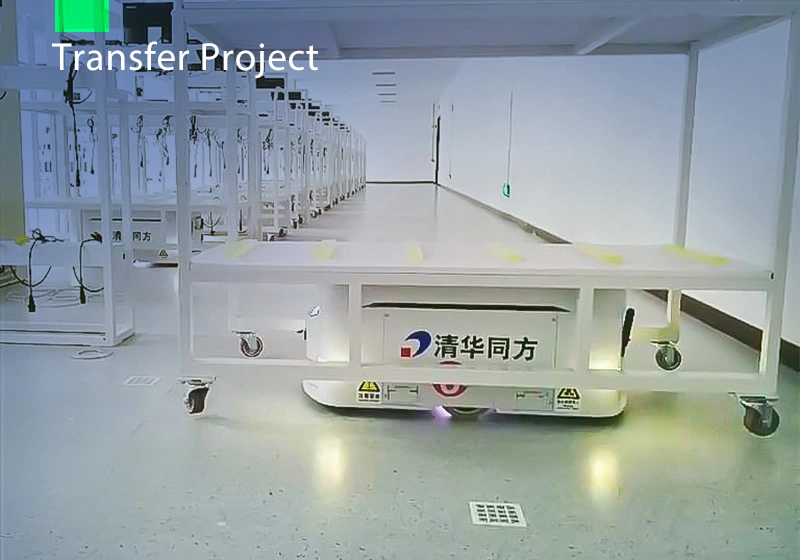

It can interact with the elevator to complete the operation of automatically going up and down floors.

The primary positioning accuracy can reach ±10mm, and the secondary positioning accuracy can reach ±5mm.

Equipped with a full servo drive, it can increase the speed quickly (0-72 meters per minute only takes 3 seconds), and has a fast rotation function (only 3 seconds for in-situ rotation)

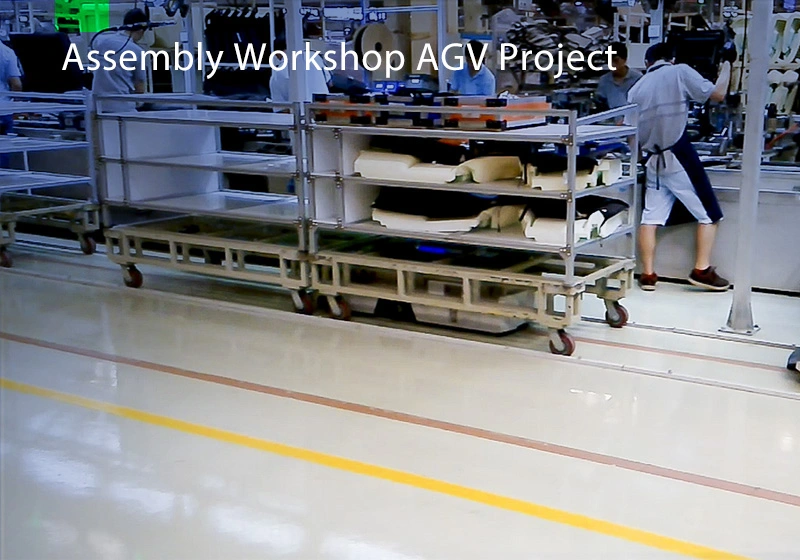

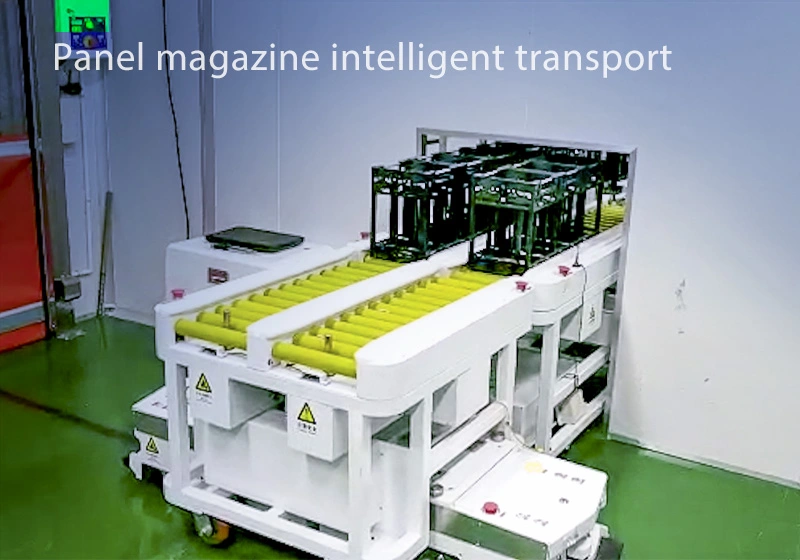

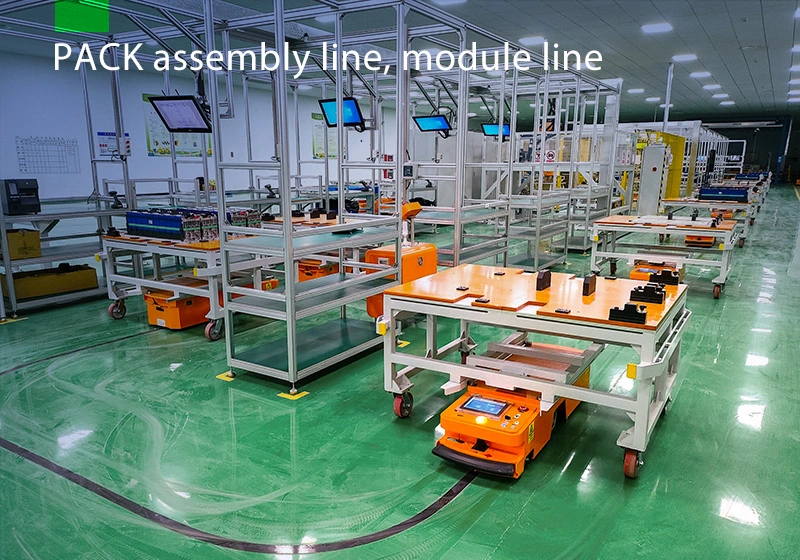

Synchronous linkage of multiple AGVs is suitable for complex material handling scenarios.

No manual intervention is required in the production process, and the scheduling system is fully automatic.

With fault self-checking function, remote fault diagnosis and self-recovery function.

When the AGV detects a low battery state, it will automatically move to the charging station for charging. The online time can reach 24 hours a day to improve productivity.

Equipped with laser obstacle detection sensor, mechanical anti-collision device and sound and light warning to ensure safe operation.

(1).webp)

.webp)

.webp)