Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

With the popularization of mechanization and informatization, relying on the development of the Internet of Things, big data and autonomous driving technology, manufacturing enterprises have begun to move towards intelligence. As the material and data carrier of smart logistics in the field, industrial mobile robots are gradually recognized and applied on a large scale in various industries, which not only relieves the pressure of labor shortage in production and manufacturing, but also improves production efficiency and improves the process of data collection. It has an epoch-making impact on production management and logistics scheduling.

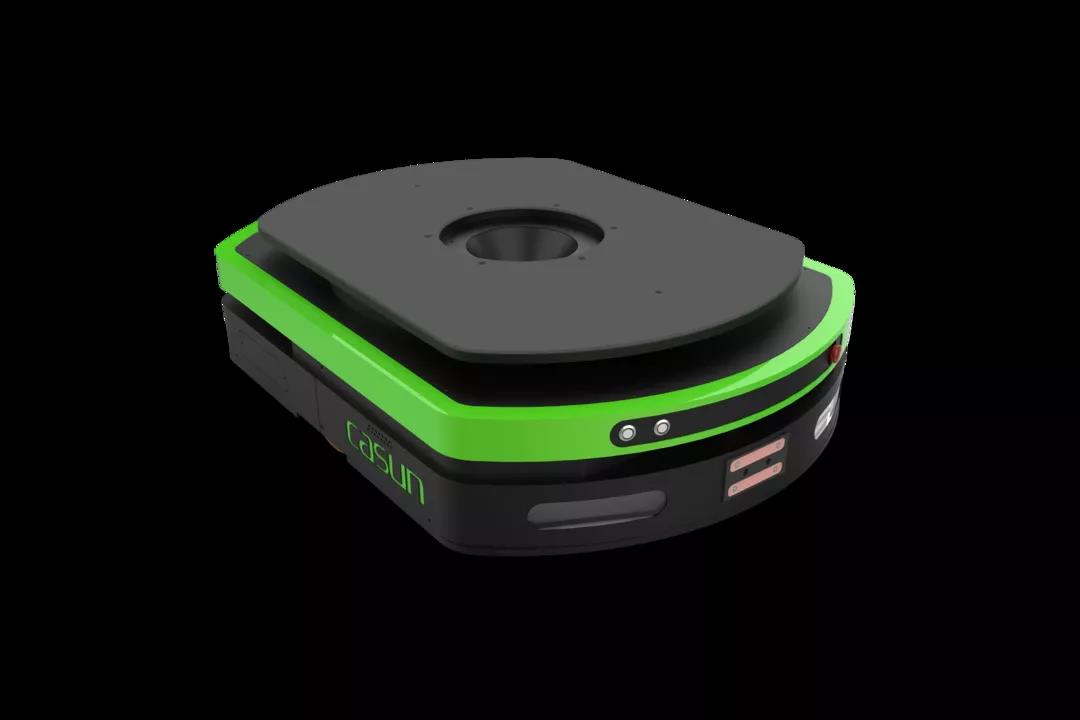

A few days ago, the warehousing site of a large tobacco company used CASUN C2-23 carrying and lifting AGV to realize the function of intelligent warehousing and sorting.

In this project, AGVs are mainly used in the process of finished products in and out of storage. AGVs are used to complete intelligent sorting and cooperate with robotic arms to realize unmanned warehousing operations in which finished products are automatically put in and out of the warehouse.

(1) Multi-positioning technology to achieve high-precision docking

AGV uses inertial navigation, visual inspection and other technologies to achieve precise positioning, with an accuracy of ±5mm.

(2) Multi-system linkage to realize intelligent sorting

The AGV fleet management system is connected with the WMS system to automatically generate tasks of picking and getting materials in and out of storage, manage the information of material located in the warehouse in real-time, and realize the synchronization of accounts and materials. It cooperates with the manipulator to realize intelligent destacking without manual participation in the whole process.

(3) Intelligent scheduling to achieve efficient application

Intelligently plan the optimal path, reduce ineffective walking, and improve operation efficiency. The AGV control system can also manage the material information in the warehouse in real-time to realize the synchronization of accounts and materials.

(4) Improve picking efficiency

The AGV conducts round trip operations 190 times per hour, once every 18 seconds on average.

(5) Improve the use ratio of storage

Seamlessly connect to the WMS system, optimize the location, path, and task allocation, reasonably plan the warehouse layout, maximize the use of space, and increase the storage location by 20%.

(6) Improve the information process

The information data of storage location, tasks of out-put and in-put of the warehouse, and on-site equipment in and out of the warehouse (robot arm, stacker, warehousing operation terminal, etc.) is managed by the customer's WMS system to monitor the status of the factory materials in real-time.

(7) Reduce labor costs

Reduce the number of personnel operations, reduce the labor intensity, reduce the error rate of operations, improve the flexible process, and save a lot of labor costs.

The product used in this solution is the latent AGV, one of CASUN's star products. This QR code robot navigation AGV has the following nine advantages:

(1) Strong load capacity

The load capacity reaches 1000KG, and the running speed can reach 90 m/min at full load.

(2) Strong adaptability to the environment

With the function of learning map by itself, the operating map can be updated independently according to the changes of the scene during operation, thereby greatly improving the environmental applicability.

(3) Can run across regions

It can be connected with a variety of channel equipment such as elevators, electronic doors, and air shower doors to achieve cross-floor and cross-regional operation.

(4) High positioning accuracy

The secondary positioning accuracy can reach ±5mm.

(5) High operating efficiency

It adopts full servo drive, which can quickly increase the speed (it only takes 3 seconds to accelerate from 0 to 90m/s), and has a fast rotation function (it only takes 3 seconds to rotate on the spot).

(6) Cluster scheduling

It has the function of multiple latent AGV working together to realize cluster scheduling.

(7) Fault self-check

It has a perfect fault self-checking function and has remote fault diagnosis and self-recovery function.

(8) Self-charging

When the power is low, it can go to the AGV charging station for automatic charging; no manual intervention is required to achieve 24-hour operation.

(9) Multiple security protection

The latent AGV is equipped with laser obstacle detection sensors, mechanical anti-collision devices and sound and light voice warnings to ensure safe operation.

In this project, CASUN's standardized service process, excellent product performance and advanced technology, and rich and efficient project implementation experience have enabled the large tobacco company to successfully achieve logistics upgrades.