Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

As the core logistics equipment in the new energy production process, mobile robots with its small space occupation, flexibility, high fault tolerance, efficient and intelligent advantages, the landing in the new energy industry is being further accelerated and is widely used.

In production, it can replace people to complete some monotonous, frequent, labour-intensive and repetitive work for a long time or work in dangerous and harsh environment.

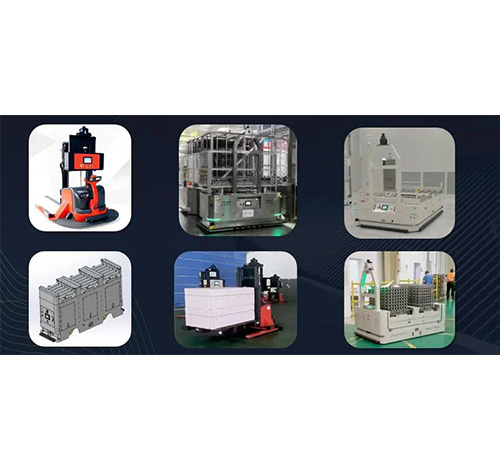

The representative products of Jiashun: C5-B1, C5-B2, C5-B3, C5-D1, C5-D3, C5-D5, C5-D6.

Fork pick-up agv mobile robots application scenario one: cathode material transfer in the front-end process

Project requirements: A new energy lithium upstream material enterprise cathode material intelligent transfer project, need for lithium raw material transfer process for intelligent logistics upgrade, to achieve intelligent logistics of the factory.

Solution.

1) The project applied 38 laser-guided fork-fetch AMRs, 7 sets of automatic charging piles, automatic weighing system, etc..

2) The data is collected through the automatic weighing system, interfaced with the production management system, and the material is called after the weight is met to realise the automated distribution of the robots.

Project effectiveness and benefits are reflected in.

1) Reduction in the number of manual workers.

Reducing logistics and distribution personnel and equipment docking personnel, optimising the operational process, saving 2-3 people per production line and improving efficiency by more than 30%.

2) System docking.

Intelligent system docking, from the dual combination of software and hardware, to achieve the ultimate goal of unmanned and intelligent.

3) Increased intelligence.

Seamless connection between processes through AGV/AMR robots to achieve data cascading and increase the degree of factory intelligence.

Fork-taking agv mobile robots application scenario two: front section process coil running

Project requirements: A new energy lithium enterprise production plant production section pole piece intelligent transportation project, mainly for copper foil, aluminum foil coil material and pole piece cache box transfer process for intelligent upgrading. The project site includes film coating, coating and roller pressing processes, with complex operation processes and cross-floor transportation.

Solutions.

(1) The project solution uses five laser-guided fork-taking AMRs, a warehouse management system and an AGV management system to form a smart logistics solution for the new energy lithium industry coil process.

2) Docking with on-site automation equipment to realize automatic material calling.

3) Docking with the lift control system to realise independent getting on and off the lift.

Project effectiveness and benefits embodied in.

1) Reduction of fixed equipment input costs: flexible process improvement, cost savings of 5 million.

2) Improved yield and accuracy: 85% reduction in defective rate and reduction in material damage during handling. Transport accuracy rate increased to 99% to meet the full production peak demand of the whole line.

3) Intelligent management: optimisation of depot position, path and task allocation.

Fork-taking agv mobile robots application scenario three: back-end process module finished products in and out of storage

Project requirements: a new energy lithium battery enterprise module finished products standing warehouse transfer project, through fork pick-up agv robot placed battery module tray, to achieve the battery module tray intelligent, automated into and out of the warehouse logistics transportation goals and tasks.

Solutions.

1) The project applied 7 sets of Jiashun intelligent stacking type fork picking type F10 series AMR, 3 sets of automatic charging, etc..

(2) Through interfacing with the customer's system and calling materials independently to achieve the logistics and transportation objectives and tasks of intelligent and automated battery module pallets into and out of storage.

Project effectiveness and benefits embodied in.

1)Reducing equipment and manpower input costs.

2)Improve the timeliness of material transportation, the accuracy rate of transportation increased to 99%, to meet the peak demand of full production of the whole line.

3)Improve the safety of product transportation and ensure the product yield.

(4) realize the whole production process intelligence, automation, from product off-line - into the warehouse - out of the warehouse of the whole process monitoring and tracking, production data statistics, report generation.