Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

With the strong growth of labor costs and e-commerce, the automation and intelligent planning of logistics companies have been accelerated. Driven by the demand for e-commerce logistics, the application of AGV mobile robots in the field of express logistics has been greatly improved.

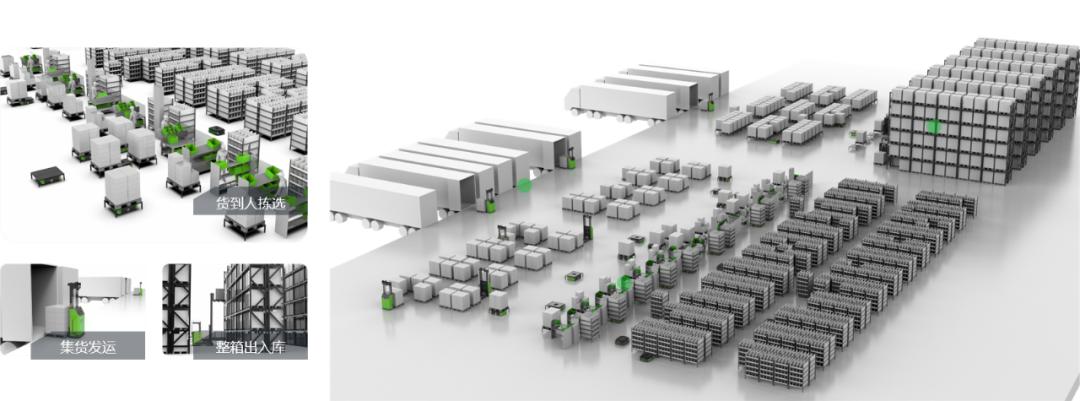

CASUN E-commerce Logistics Cold Storage Food Transshipment Project Case

1. AGV mobile robot project background

The mobile robot in the cold storage food transfer project of the logistics company under the largest direct e-commerce platform in China is mainly used for the entry and exit of food products into and out of the cold storage process. The mobile robot is used to realize intelligent handling, and it is connected with a variety of roller line equipment to complete the automatic entry and exit of the finished product into the cold storage.

2. Project difficulties of agv mobile robots:

1) The storage space is small, the load is heavy, and the rhythm is fast, which requires high AGV/AMR operation path planning capabilities;

2) There are many roller devices that need to be docked, and the requirements for the docking accuracy and stability of AGV/AMR are high;

3) The working environment temperature is low, only -3°C, and has high requirements for the low temperature adaptability of electronic and electrical components of AGV/AMR;

4) Highly flexible scheduling requires efficient adjustment of logistics lines according to shipment volume requirements;

3. The functions and benefits provided by the agv mobile robot:

By introducing AGV/AMR and intelligent management system, the labor intensity of porters is reduced and their work comfort is improved. In turn, it reduces the direct labor cost and management cost of the enterprise, realizes fully automatic unmanned warehousing, and improves the utilization rate of warehousing and the efficiency of inbound and outbound warehouses.

4. Project plan of agv mobile robot

1) The project applied 12 QR code-carrying roller-type AGV robots, 4 sets of automatic charging columns, and 1 set of warehouse management system.

2) Through docking with the MES system, autonomously order materials, automatically dock with the line body, complete cargo transfer and automatic warehouse delivery, and realize automatic collection of information.

5. Solution advantages of agv mobile robot

1) Meet multiple transportation needs: AGV adopts QR code navigation and steering wheel drive, which can realize 360-degree in-situ rotation and lateral movement, reducing the requirements for passageways.

2) High reliability: the efficiency of the AGV truck is higher, and the driving path and speed are controllable, the positioning and parking are accurate, and the central management system of the AGV truck can monitor the AGV truck throughout the process, which greatly improves the reliability.

3) The data chain is complete and traceable: the collection and entry of transshipment material information is realized through the AGV intelligent control system, and the complete traceability of the data chain is achieved.

4) Reduce labor costs: reduce management costs and reduce potential health damage to personnel caused by low temperature environments.

6. Customer benefits of using agv mobile robots:

1) Higher work efficiency: avoid the error rate in the process of manual sorting and handling, improve handling efficiency and accuracy, and increase the overall inspection and search ability by more than 30%;

2) Guaranteed storage utilization rate: no need to transform the original storage location, realize unmanned transfer in the existing environment, increase the site utilization rate by more than 40%, and ensure the storage utilization rate;

3) Reduce potential occupational hazards: save a lot of labor costs, improve employees' work comfort, and reduce employees' potential occupational hazards.