Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Automotive painting materials enjoy the latest technology and cutting-edge applications in the painting industry, and are regarded as an important indicator to measure a country's painting level. Automotive paintings and their technologies directly determine consumers' aesthetics and experience of using cars. In order to meet the increasingly diversified and personalized requirements of consumers, various automobile manufacturers have increased the research and upgrading of automobile painting technology.

This article combines CASUN's 14 years of experience in the implementation of smart logistics in the automotive field, and discusses how to solve the pain points of car body painting, formulate the planning direction of intelligent painting and the application of automated guided vehicle China in the painting workshop.

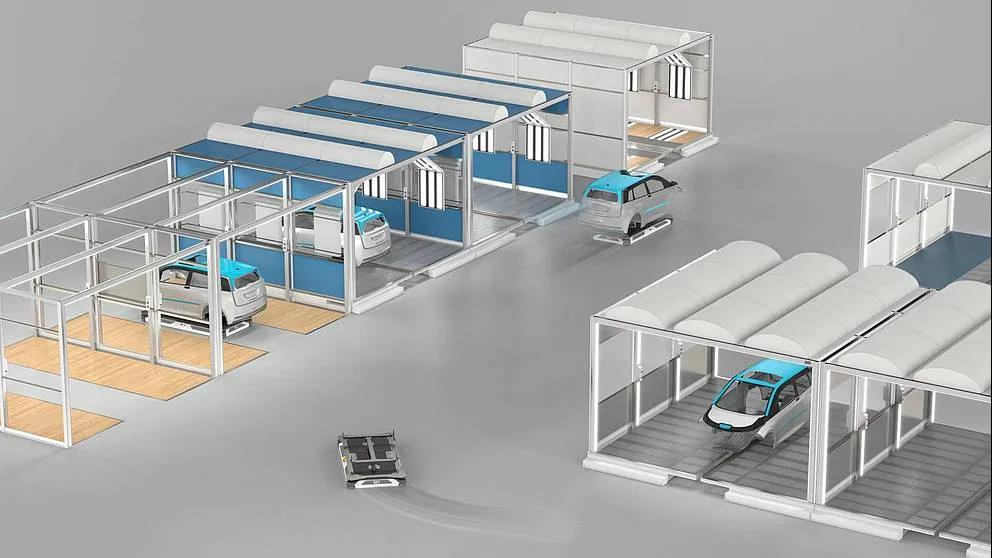

The painting process generally includes steps such as cleaning, electrophoresis, paint, varnish, etc. The painting workshop has a long conveying distance. The total conveying distance of the 60JPH workshop is as long as 6 or 7 kilometers. Intelligent conveying equipment can be widely used in painting material warehousing, material handling, material warehousing, material preparation, distribution, painting production line, line side transfer, etc. Of course, CASUN AGV plays an important role. For example, the painted body in white is automatically transferred by AGV.

CASUN has been focusing on the AGV field for 14 years. As a professional enterprise providing intelligent logistics comprehensive solution service, it has a lot of practice in the automobile intelligent painting workshop. The intelligent logistics upgrade of the painting workshop focuses on the upgrade and planning of the intelligent system.

The paint itself is very harmful to the human body, and the entire painting production line is almost an unmanned production line. The manual work is mainly in material scheduling, paint mixing, production line monitoring and equipment support services. In terms of the degree of automation of a single production line, 100% automation is basically achieved, and AGV is more widely used, which is mainly used in the transportation of car bodies.

(1) AGV application benefits

① Cost reduction and efficiency improvement

AGV/AMR can achieve 24-hour high-speed repeated operation, and the work rhythm is much higher than that of labor, so it can greatly improve the work efficiency of the painting workshop, and also reduce labor costs and management costs.

② Safe and reliable

Avoid repeated, boring processes and the impact of heavy physical labor on workers' status, avoid quality decline and accidents caused by this, and effectively improve production safety and product quality.

③ Green environmental protection

AGV/AMR can work in a dark field environment and can reduce the working space, thus effectively reducing the energy consumption rate and material consumption rate.

④ Flexible production

AGV/AMR can be increased or decreased flexibly, promoting the flexible process of production and manufacturing, basing production on sales prospects and achieving fast delivery of orders.

① Accurate docking between AGV and spraying production line

The spraying line of the painting technology workshop is relatively fixed, and the workload of each additional model or location transformation is very large, and even it needs to be dismantled and rebuilt. In order not to affect the production of the model in production, the transformation time is usually very short, and the transformation is difficult.

Because the position of the AGV trolley is not fixed, the production site can be changed at will, breaking the mode that the line has a fixed demand for space.

The painting workshop has a high degree of automation. With the support of the intelligent management system, the application of AGV needs to focus on the docking with the original spraying system and the optimized management of the handling route, so as to give full play to the flexible production advantages of AGV in the painting technology.

② AGV anti-paint performance

The spraying workshop has a large amount of paint. During the transfer, the AGV will inevitably come into contact with the paint when entering and leaving the spraying workshop. Therefore, the AGV needs to have certain paint resistance and solvent resistance, which is easy to clean and keep clean.

③ The AGV is highly adaptable to the workstation

After the body in white goes through the spraying process, the weight of the body increases, generally around 1000KG. The AGV used for handling needs to have a certain rigidity to achieve the precise docking with the workstation under different load conditions.

AGV replaces traditional fixed conveyor lines to make production more flexible, breaks the platform limitation of traditional production lines, and can realize mixed-flow production of different platforms and more models; at the same time, it breaks the boundaries of production processes, and can formulate corresponding production processes and production path according to different technologies, so as to make more rational use of production resources and promote the development and realization of "Industry 4.0" in the automobile industry.

CASUN is one of the earliest enterprises in China to provide intelligent manufacturing solutions for the automotive industry. We will be committed to providing a complete set of solutions for the "4.0" intelligent manufacturing of automobiles, accelerating the intelligent upgrading of the automotive industry!