Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

Focus on AGV industry for 18 years

At present, Chinese society has entered a new stage of development: population mobility has increased, individual needs have increased, and China has gradually entered an aging society. All of this is forcing the rapid transformation of the manufacturing industry. For the intralogistics industry, it will bring disruptive changes, but it is also a very big opportunity. In fact, the fundamental goals of China's "Made in China 2025" and Germany's "Industry 4.0" are the same: flexible production, adapting to small batch, multi-variety, customized production models; real-time processing, recording, and transmission of production data; materials Real-time communication between the management system and intelligent production and logistics equipment, task execution; reduce labor intensity, improve worker labor productivity; save energy, reduce consumption, and reduce carbon emissions.

Intralogistics equipment manufacturers at home and abroad and end customers in the manufacturing industry are actively making beneficial attempts. Internationally, Europe, especially Germany, which has put forward the goal of Industry 4.0, has a solid foundation in this regard, with a lot of R&D investment and the highest level of technology. "Production, learning and research" are closely combined, and the research and development of logistics equipment is closely integrated with the development of manufacturing logistics management concepts to achieve lean management of production processes.

The production mode of many enterprises in the traditional domestic manufacturing industry is based on large-scale production, which reduces costs and improves product competitiveness by mass production. The internal logistics equipment to match it generally adopts fixed conveying equipment. The so-called automation and intelligent upgrade of the manufacturing industry is actually to meet the needs of the future manufacturing industry to transform into a small batch, multi-variety, user-customized, and high-value-added production mode. The image is that the original L-shaped production line with one process connected to one process needs to be transformed into an independent island-type production line. The production workers flow between the island-type production lines according to different product requirements. At this time, the original fixed conveying Equipment is bound to be replaced by AGV.

AGV needs to issue instructions according to the ERP system to complete parts extraction, auxiliary assembly, finished product delivery and other work. Therefore, in the future high-end manufacturing industry, AGVs are widely used and have huge market potential, playing a very important role.

Different industries in China have different needs for the AGV industry. For the assembly workshops of automobiles and engines, AGVs are part of the production line and transport products between various processes. There are many AGVs, and sometimes they need to coordinate with other automation equipment. For system scheduling, system stability And the repeated positioning accuracy of the vehicle is very high. For most manufacturing enterprises in transition, the use of AGVs is still in its infancy, mainly used for material handling between warehouses and production lines or between production lines, replacing traditional forklifts and ground cattle that require human operation. With the proposal of "Made in China 2025", many companies have taken AGV applications as part of the construction of intelligent factories, and considered them as a whole in combination with the assembly process and ERP system.

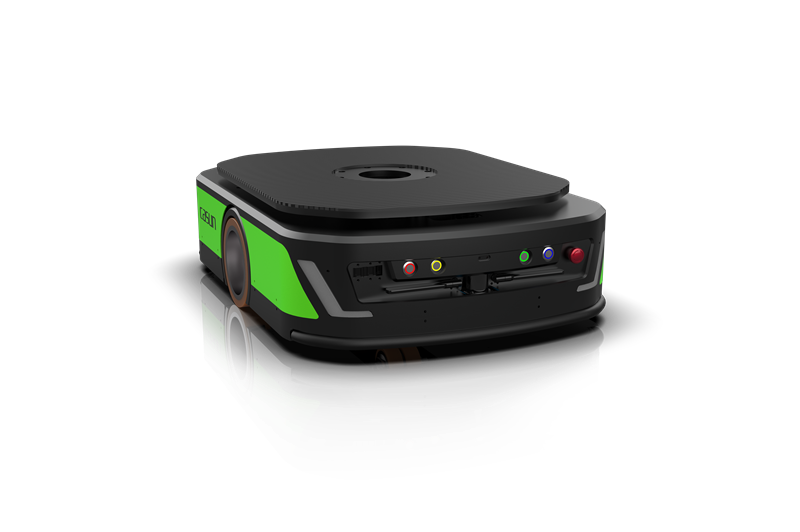

Now, there are many AGV manufacturers and the competition is fierce. However, as mentioned earlier: there are still certain technical thresholds for the dispatching system of multiple vehicles, the body design with space size requirements, and the precise driving technology of bicycles. CASUN has mastered the domestic leading technology in AGV manufacturing and has more than 100 patent certificates. It is a long-term partner of many large enterprises at home and abroad, and we believe it will be your first choice for cooperation.